ENABLING SILICON SOLUTIONS FOR LI-ION BATTERIES

Safe.

Scalable.

Cost-effective.

The Li-ion battery problem:

Everyone wants electric vehicles to drive further, charge faster, and cost less using a greener battery. Problem is, today’s Li-ion battery performance is limited by performance thresholds of current anode material, graphite.

Silicon + Advano unlocks compelling performance gains at lower cost per kWh.

Silicon

28.085

Silicon has 9x the energy density of graphite.

Incorporating silicon-based active anode materials inherently improves Li-ion battery performance.

Advano’s silicon-based materials enable a cost-efficient means to a better battery.

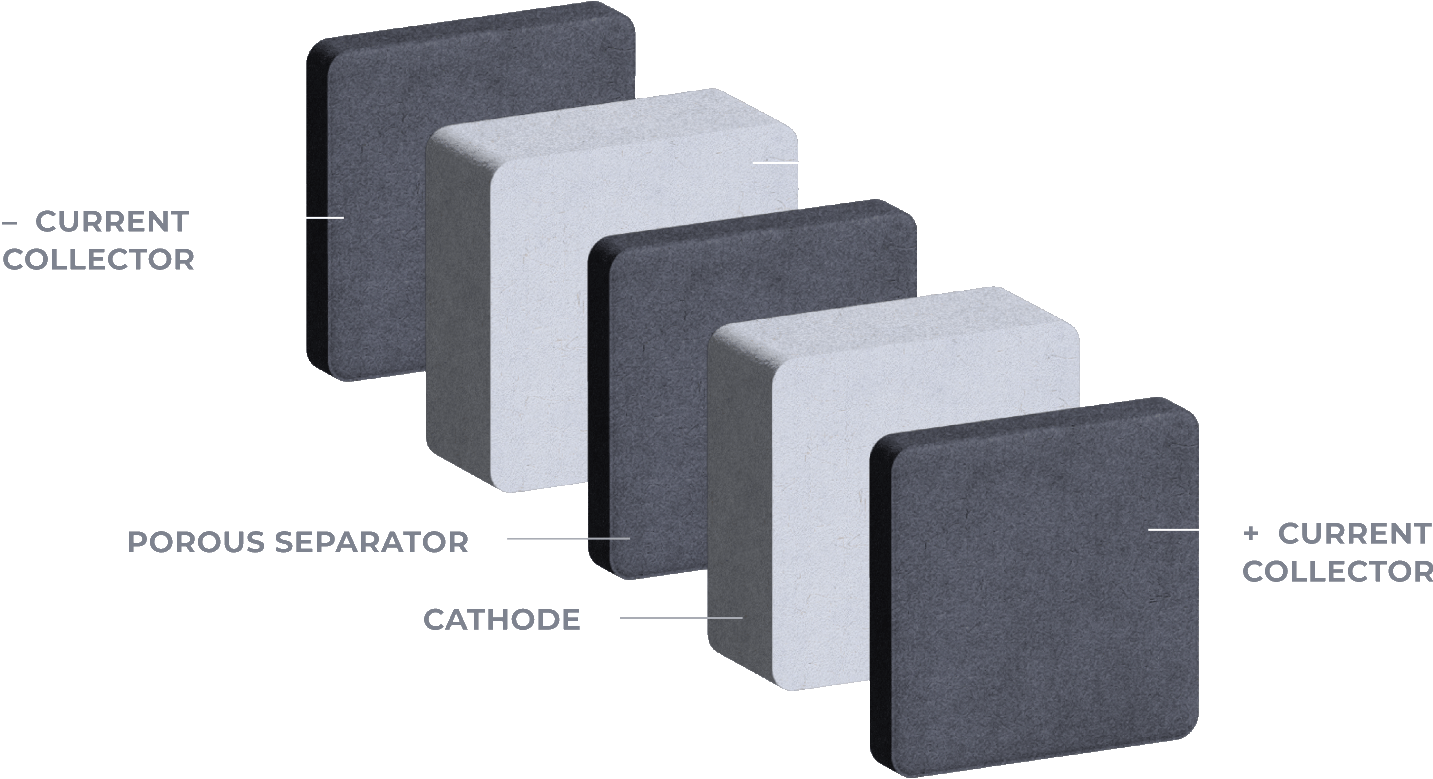

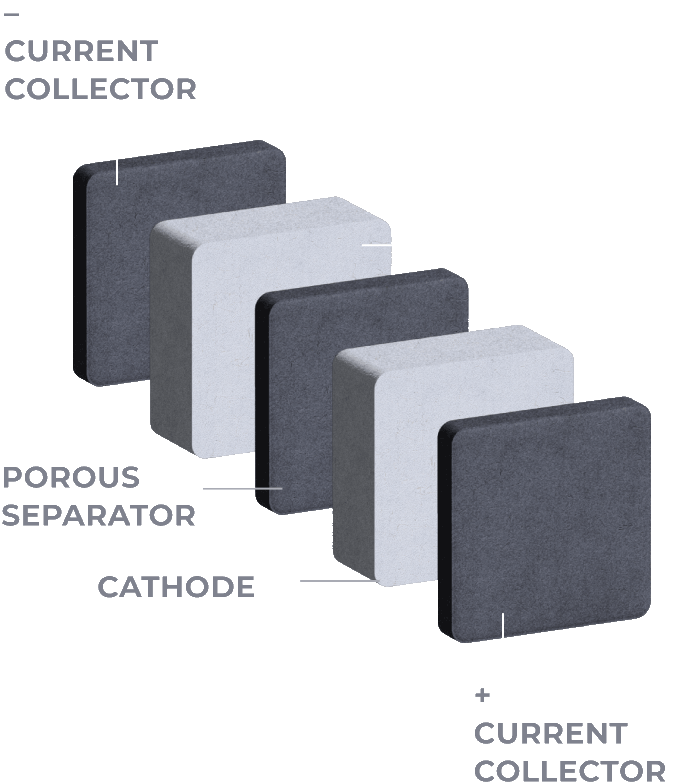

Advano enables better battery performance and lower costs with a “drop in” of highly-engineered, silicon active materials into existing Li-ion battery designs, primarily for electric vehicles

Our process places a fundamental emphasis on environmental sustainability by avoiding the hazardous challenges of silane gas.

We capitalize on methods and materials that are not dependent on constrained supply, enabling seamless expansion or adaptation to meet growing demands or evolving customer requirements. This flexibility is integral to our operations. Moreover, we utilize metallurgical-grade silicon, which is abundantly available and cost effective, ensuring the scalability and cost-efficiency of our process.

We utilize readily available manufacturing equipment and low-cost precursor materials that not only offer inherent scalability but also reliability. By leveraging well-established and proven manufacturing processes, we guarantee operational efficiency, reduce production costs, and ultimately provide customers a cost-effective solution.